As a tool for energy saving, environmental protection and turning waste into treasure, the briquetting machine must follow standard operating procedures during production and use, reasonably arrange production time, and strictly prohibit continuous and uninterrupted operation, which exceeds the tolerance of the equipment. In addition, when starting the equipment, you must pay attention not to start with a load, otherwise there will be a stuffy phenomenon, which will affect the motor or even burn the motor. Next, the briquetting machine manufacturer will explain how to use the briquetting machine.

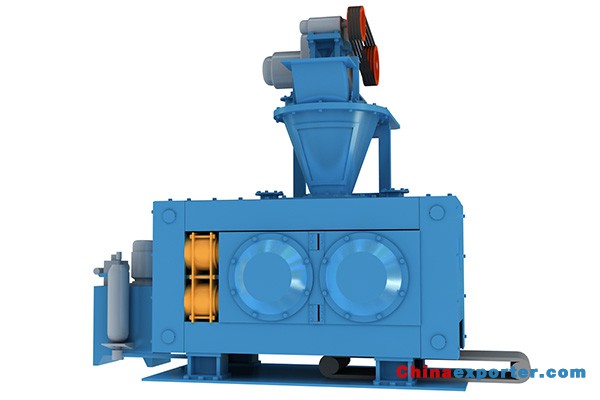

1. Host (mechanical molding)

Check whether all parts of the electrical appliance are normal before starting up. Check the alignment of the die holes of the two rollers. If they are not aligned, open the gear guard, loosen the six screws on the adjustment plate on the driven gear, turn the passive roller forwards and backwards to align the die holes of the two rollers, and tighten the screws. The working roll spacing should be kept between 0.5-0.8mm. If it is too large or too small, you can loosen the passive roll, the bearing and wire drawing, adjust them, and tighten the screws and wire drawing after adjustment. After starting to produce the finished product, check whether the upper working surface of the double roller is compatible. If there is an error, remove the protective cover on the large gear and loosen the outer ring screw of the driven roller gear for adjustment.

2. Host (Hydraulic Forming)

First check whether the electrical appliances work normally, and whether the steering of the mold roller and hydraulic mercury is positive. Then check whether the die holes of the two rollers are aligned, the distance between the two rollers should be between 0.4-0.6mm, and it should be adjusted if it is too large or too small. If the two-roller die holes are not aligned, the gear guard should be opened, loosen the six screws of the adjustment plate on the driven gear, turn it forward or backward, and tighten the screws after the adjustment is correct. If the distance between the two rollers is large or small, the passive (moving) shaft should be adjusted on the four adjusting wires on both sides of the driving wheel. After everything is normal, the machine oil should be added to the reducer. Add the hydraulic oil to the hydraulic mercury tank. Start the pressure test, which means the bottom of the pressure regulation is 9MPa and the high regulation is 12MPa. Start trial production only after everything is normal.

...

Specific click to visit:https://www.zymining.com/blog/use-of-briquetting-machine/