In modern industrial production, in order to save raw materials, various equipments in various industries emerge in endlessly. As an important equipment for processing and pressing and reusing, the ball press machine will inevitably have various wear and aging in use. important work components in the ball press machine Roller skins are often replaced after being worn.

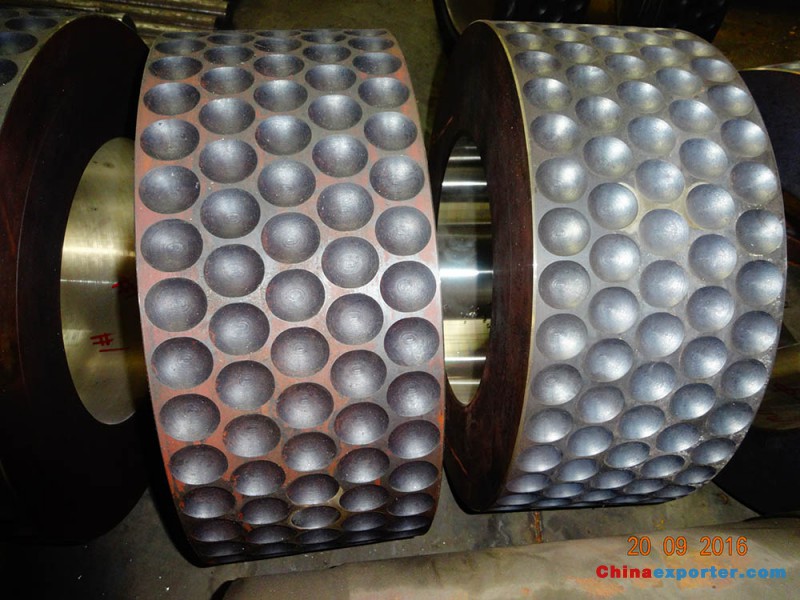

The roller skin is a cylindrical member with a ball socket dug in the outer layer wrapped around the roller core of the ball press. Usually, the pressing of the material depends on the hydraulic drive roller, which is formed by the ball socket of the roller skin, as a very easy to wear ball pressing mechanism. Frequent replacement is unacceptable to the operator, but the roller skin of the ball press after wear cannot meet the production requirements, and it ca n’t be replaced without replacement. It is very important to maintain the roller skin during use. The specific ball press What is the maintenance method of the roller skin?

1. The roller skin of the ball press machine must be installed correctly

There are four installation methods for the roller skin of the ball press. Different briquetting machines use different methods, but the installation standards are the same. First, the installation of the roller skin cannot be misplaced. If the roller skin is already misplaced during installation, then Not to mention the production, the shape of the ball and socket on the roller skin must be aligned, otherwise problems such as no ball, loose ball, and unrealistic spherical shape of the briquetting machine will occur; at the same time, because of the misalignment between the roller skin and the ball and socket The edges of the dimples wear on each other, and the roller skins will need to be replaced after a long period of time.

......

Details can be accessed by clicking:http://www.zymining.com/blog/what-are-the-maintenance-methods-of-the-roller-skin-of-the-briquetting-machine/